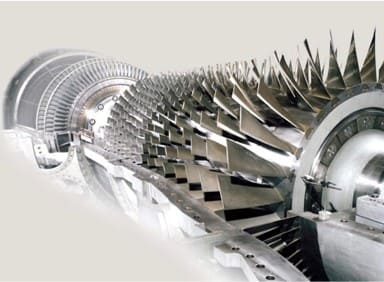

Specialist in thermal spray surface coatings

Target sectors

Production Equipment

- 5 projection cabins HVOF-LF, Plasma, Cold Spray, Arc and Oxy-Gaz

- Honeycomb soldering equipment and vacuum treatment

- Machining, grinding and polishing equipment

- 1 Large size digital control turning lathe

- Machine park with digital control

Maximum capacities:

- Diameter : 2,2 m

- Lengh : 6 m

- Weight : 10 tonnes

Advanced coating technologies

We are expert in coating technologies adapted to your processes and environment.

- Thermal spray : HVOF LF, plasma, electric arc, cold spray

- Soldering and vacuum processing

- Wide range of roughness : from Ra 0.002μm to Ra 20μm

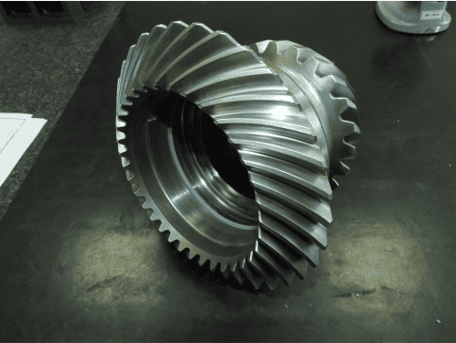

Expertise in machining and grinding

Machining and grinding of parts of various sizes in the unit or series.

- Machining

- Polishing to obtain the required roughness

- Grinding (4 cylindrical grinding machines)

Control equipment

Control and measuring suit the specificity of our activity : dimensional, geometry, roughness, hardness, etc…

Air-conditioned, our laboratory is also qualified for aerospace industry.

We are also able to carry out inspections on your site.

Control equipment

Control and measuring suit the specificity of our activity : dimensional, geometry, roughness, hardness, etc…

Air-conditioned, our laboratory is also qualified for aerospace industry.

We are also able to carry out inspections on your site.

Certification

Latest news

New cylindrical grinding machine

In 2024 September, we invest a new equipment : a digital control grinding machine ! It is able to handling large parts up to 1.80 m in length and a diameter of Ø450 mm. This machine can also process complex shapes, allowing us to push the boundaries of precision and...

Projet CLiCAM

Ouest Coating becomes a member of the consortium. Objective: Allow hight level scientists to meet industrial needs on new coating. applications. https://clicam.eu/introducing-consortium-members/ouest-coating-pmg/